"In order for data chains to get from A to B seamlessly and without errors, IT systems in the workshop must talk to each other. Isolated solutions put obstacles in the way of this goal."

KEVIN DEWI, COO

Digitization is knocking down doors everywhere, bringing along changing customer requirements, cutting-edge technologies, and thus new competitive conditions. These developments do not stop at the automotive industry. The automotive aftermarket is particularly affected. With an expected business volume of around 1,200 billion euros by 2023, it is the strongest profit earner in the industry (McKinsey, 2018). Trends such as the increasing networking and automation of processes are presenting manufacturers, wholesalers, and end-users with new challenges, making digitized business models the standard. Ready or not, the change is happening. Use it for your own business!

Changing customer expectations due to almost unlimited possibilities for obtaining information, the electrification of vehicles, and the appearance of new competitors in the market are pushing analog workflows to their limits. An industry segment stuck in conservative thought structures yesterday is increasingly becoming an innovation driver with the generation change and against the background of an “amazonized” society. The survey results of the association Qualität ist Mehrwert in 2021 also confirm this: Most garages surveyed assess digitization positively and see it as a development that ensures faster processes and significant work simplifications.

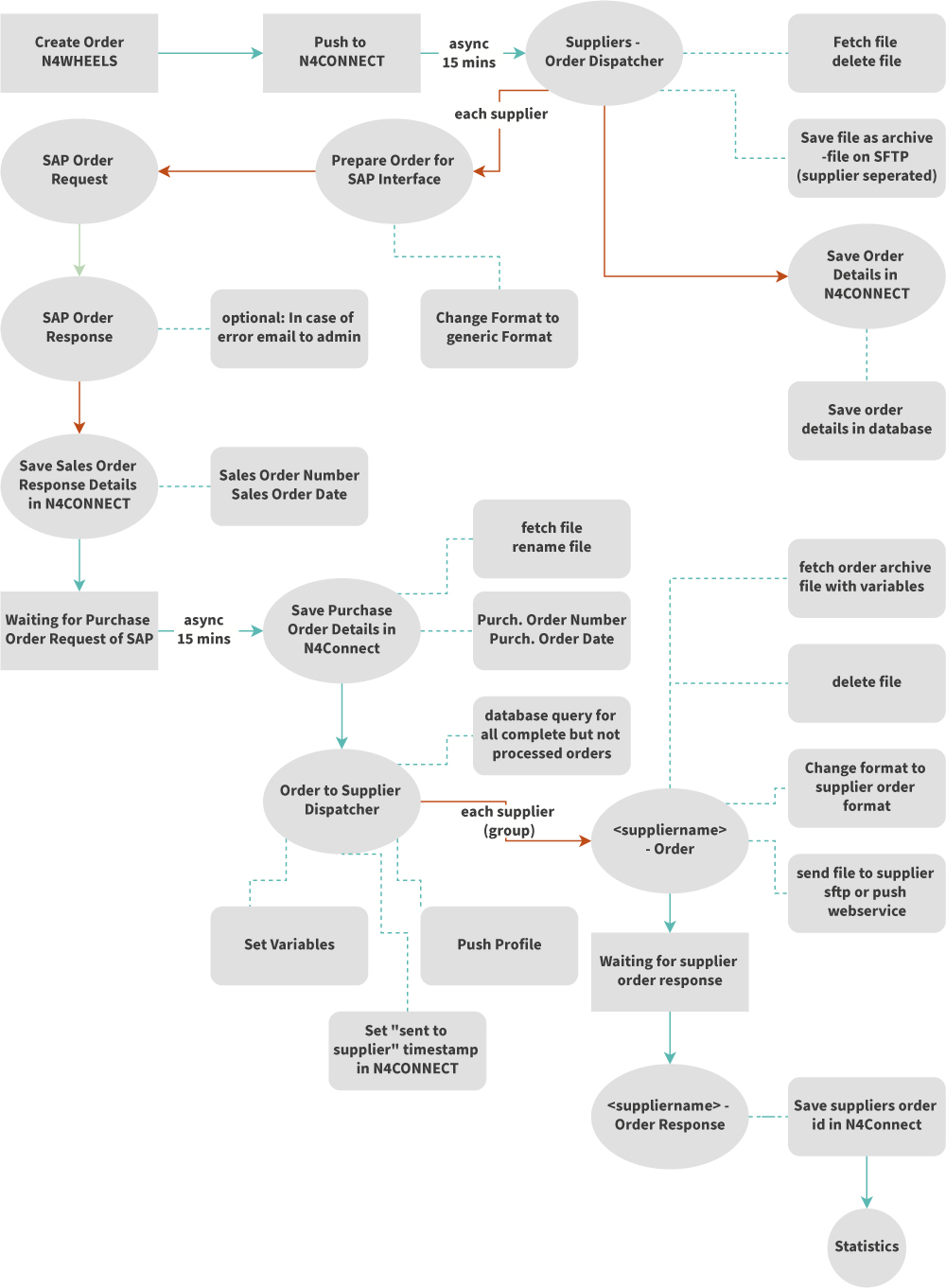

For some time now, a term has been circulating in the industry. Its almost inflationary use distracts from its actual relevance: holism. So far, so abstract. But what is the buzzword all about? Simply put, it describes the digital networking of all systems used in operations – from appointment recording to service acceptance and procurement to invoicing. Here, however, challenge and opportunity go hand in hand. After all, automated communication between individual software tools only works if suitable interfaces are integrated as a first step.

"In order for data chains to get from A to B seamlessly and without errors, IT systems in the workshop must talk to each other. Isolated solutions put obstacles in the way of this goal."

KEVIN DEWI, COO

It is only through them that a hurdle-free data transfer becomes possible. Workflows no longer break off during processing because the responsible employee takes a lunch break. Instead, questionable data volumes run without detours into the merchandise management system (MMS) and are fed to connected systems. This reduces the error rate when placing orders and ensures optimized workshop processes and a significant performance boost.

Automotive customers, whether workshops, (wholesale) dealers or end consumers, are more informed and self-determined than ever before, thanks to the unlimited possibilities of the World Wide Web. This is also triggering drastic changes in the aftermarket. More and more users are using digital channels to get an overview of product costs and quality. Not only comparison and recommendation portals are gaining importance. The tendency to make online purchases and transactions is also increasing significantly. And ensures that all players have to recapitulate their position in the B2C & B2B e-commerce business. In this respect, McKinsey (2018) predicts that workshops will further increase their e-commerce activities on dealer-independent B2B platforms by 2030 and that end customers will also increasingly purchase spare parts via digital platforms. Where previously fixed price conditions and contracts determined purchasing, now almost unlimited information and procurement options ensure more price transparency and fairness in the digitalization field.

Enormous amounts of data are racing toward us – quite literally. The progressive electrification and networking of vehicles provide the players in the automotive aftermarket with important information on driving behavior, mileage, and odometer readings, among other things. However, this unpolished treasure trove of data can only be used comprehensively through so-called big data statistics and advanced analysis methods. Used individually, this combination offers the opportunity to examine the customer’s behavior and needs and optimize value chains accordingly. While workshops can, for example, predict possible maintenance visits, related services, and spare parts purchases, fleet operators can organize their activities more easily thanks to data-based forecasts. This ensures more efficient business processes, higher revenues, and greater satisfaction on the end user’s part.

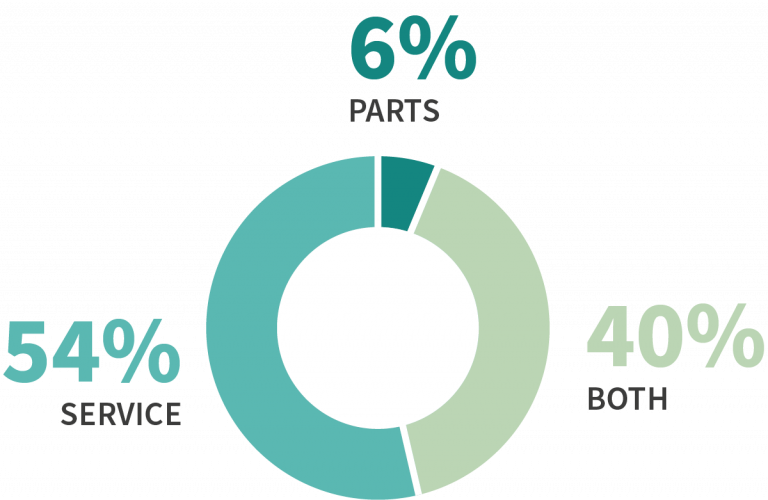

The digital transformation era entails a customer needs shift from B2C to B2B. With the advent of technological innovations and a growing number of touchpoints along the value chain, automotive players must also expect increased end-customer involvement in the market. The service segment is primarily affected by this. It can be observed that workshops are gradually handing over individual services to the end customer during their digitalization measures (keyword: self-services). In practice, it looks like this: The customer makes his appointments or calls up the repair status of his vehicle online. This significantly speeds up individual service processes and relieves the specialist staff’s workload. Enhanced with specific expert knowledge, digital service tools also help workshops to offer better customer support more quickly.

So let’s take a little excursion into the digital garage of tomorrow: analog workflows are mapped in a holistically digitized way. Enriched with relevant customer data, software solutions are seamlessly integrated into the existing IT system landscape and thus enable an automated data flow between the individual departments. These digitized process chains reduce the administrative workload for employees to a minimum and instead free up space for what is important to workshops – their core business. This closes the (opportunity) circle.

For holistic digitalization and process optimization in the automotive aftermarket to work, all players must keep in mind: Change starts with people, more precisely, with the players who benefit from it. This is not primarily the management but rather the workshop personnel themselves. Digital transformation is only truly successful when digital processes are adapted to the needs of employees and thus make work easier.

"To achieve real success through digitalization, all stakeholders – first and foremost, the employees – must be on board from the beginning."

ALEXANDER KIRCH, solution manager

The automotive aftermarket is an “old” industry. Analog workflows established here have usually grown over several decades and are correspondingly complex. A mindless imposition of digitalized workflows is not expedient. For workshops to stand out from other market participants and define clear USPs, existing process structures must be authentically and sustainably optimized. Without considering individual customer needs, “One-fits-All” quickly becomes “One-fits-None.”

LENA SCHÖNLEBEN

junior marketing manager

KEVIN DEWI

COO

ALEXANDER KIRCH

solution manager

PATRICK LANG

head of automotive products

McKinsey & Company (2018): Ready for Inspection – The Automotive Aftermarket in 2030.

Qualität ist Mehrwert (2021): KFZ-Werkstatt Befragung. Digitalisierung in Werkstätten.